Well-functioned railway transportation has a direct bearing on the nation's livelihood while and the damage detection of rail tracks serves as an important means to ensure the safe operation of trains. Damages on track surface are shown in the figure below. At present, the detection relies on the imaging device on each section’s detecting vehicles for high-definition images, followed by manual check, exposing problems such as low efficiency and strong tardiness.

Chengdu SinoRail Electronics Co., Ltd employs PaddlePaddle, an open-source deep learning platform, to develop an intelligent online track inspection system based on embedded GPU, which uses multiple NVIDIA Jetson embedded modules as computing units to detect the collected track pictures in real time and identify damages on the track surface.

Related Product

PaddleDetection

Scenario Analysis

Measuring business requirements

The track inspection device is a subsystem of the company’s integrated inspection vehicles for track, network, and tunnel, and is installed under the vehicle. In the course of driving, the rail surface and its fasteners are scanned and imaged while the edge embedded GPU device is leveraged to detect the surface and its fastener defects in real time. The detection results are presented through the in-vehicle display system and confirmed by the analysts as the last step to form defect reports.

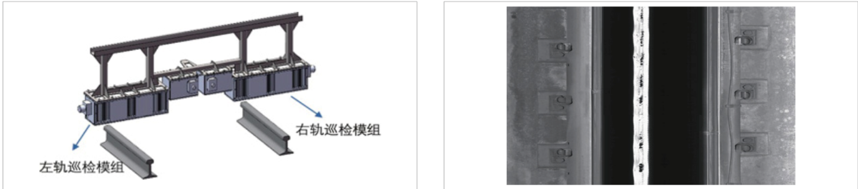

The Track Inspection Device

The device comprises left and right track inspection modules, each of which consists of a line-scan digital camera, a laser light source, and an image acquisition card, and is further divided into imaging blocks targeting track surface, inner track, and outer track.

Technical Solution

First, stitch the images of opposite directions for the first round of identification targeting key components and some defect features in the target detection model. The defect type is then derived taking the priori in consideration, and the results are filtered by the classifier in the second round to further promote the accuracy.

Actual effects

Key Tuning Processes

The accuracy witnesses a huge leap based on the collection of data and defects from 4 operations, the detection of missing bolts and defective spring rods, and the adoption of direct detection in the filtering stage[zy1] .

Detection Results

For a 40,770-meter urban underground railway section, 40,770×6 frames of pictures are collected and an inspection speed of 30FPS/road is reached, meeting the standard of a qualified launch.

· Missing spring rods:32/1001 upgraded to 29/73, among which 3 defects are classified as defective spring rods.

Company Profile

Chengdu SinoRail Electronics Co., Ltd, established in 2011 and located in Southwest Airport Economic Development Zone, is a high-tech enterprise focusing on the R&D, production, sales, and service of various products in the field of the high-speed electrified railway, urban rail transit and power supply monitoring. The company, through technologies such as big data, artificial intelligence, cloud computing, and the internet of things, provides an end-to-end solution that combines terminal, data, application, and service for China Railway (CR), The Railway Bureau, and power supply sections by deeply integrating all-professional railway detection technology.